What is Needle Felting?

Needle felting is a creative craft that involves sculpting shapes and figures using wool and special felting needles. It’s a simple yet versatile technique that allows you to create amazing creations with just a few supplies. Let’s take a closer look at the key components of needle felting.

The Wool

The Wool

Wool is the primary material used in needle felting. Each wool fiber is covered in flat, overlapping scales, which, when agitated, come into contact with each other.This contact locks the fibers together, causing the wool to felt. The orientation and direction of the scales are random, ensuring a secure bond during the felting process.

The Felting Needles

Felting needles are unique tools designed with tiny barbs on the end. These barbs, aligned in one direction, play a crucial role in felting. When the needle is repeatedly stabbed into the wool, the barbs pull the wool in but prevent it from sliding back out. This action tangles the wool fibers and causes the scales to interlock, resulting in felting.

The Felting Cushion

A cushion or pad is essential for needle felting. It provides a surface to work on, allowing the felting needle to penetrate the wool without reaching the table or your leg. The cushion absorbs the needle’s impact, making the felting process smoother and more comfortable.

The Process

The Process: To start needle felting, roll up a small amount of wool and begin stabbing it with the felting needle. As you repeatedly stab and turn the wool, the needle pulls more wool into itself, and the fibers with their scales interlock and felt. With continued stabbing and turning, a firm round shape begins to form. Additional wool is added as needed to sculpt and shape the creation.

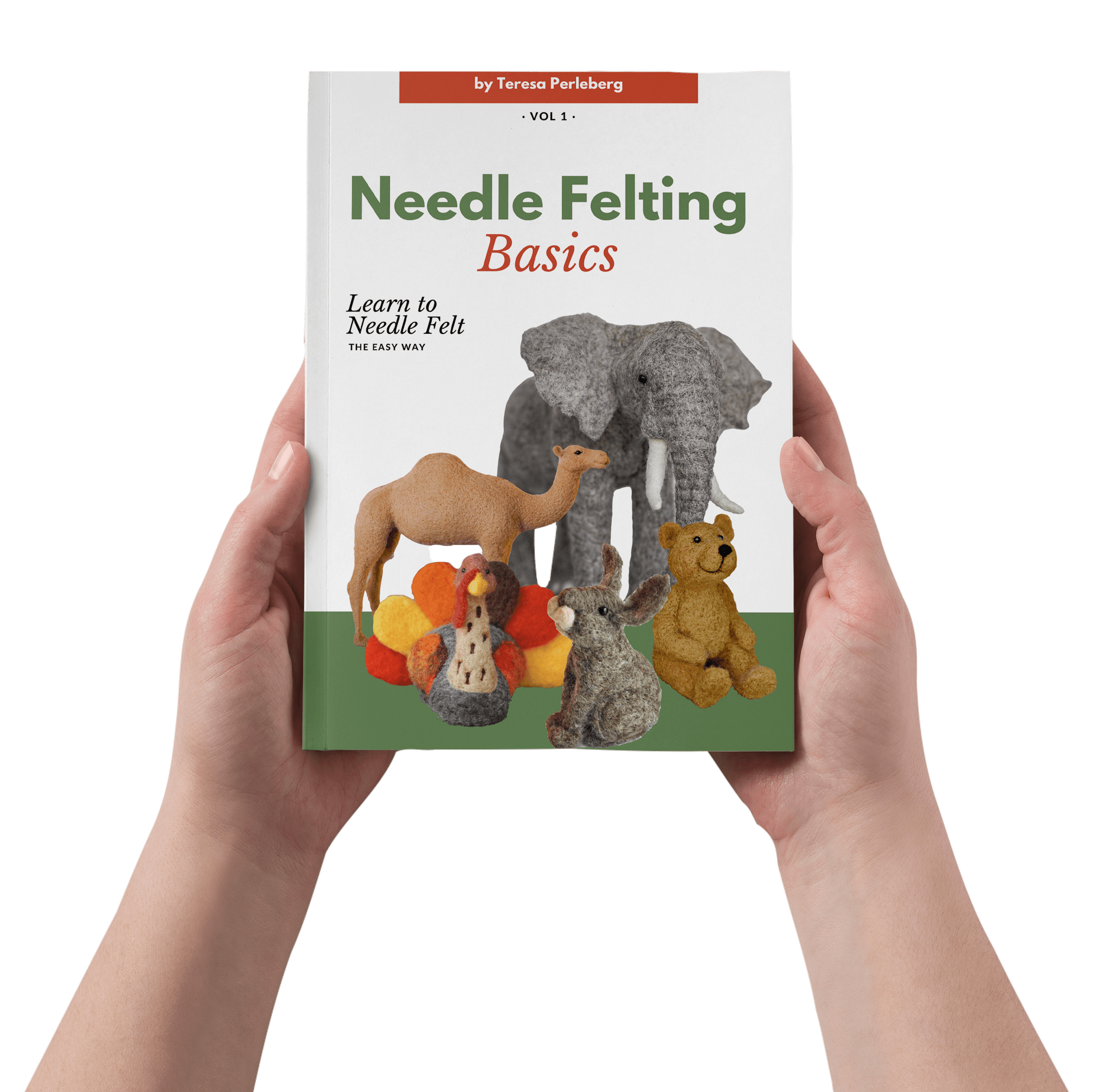

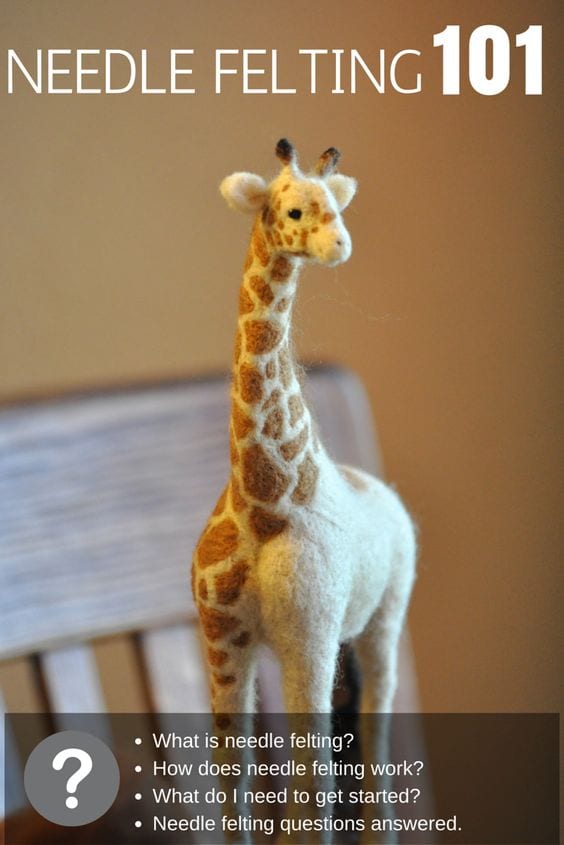

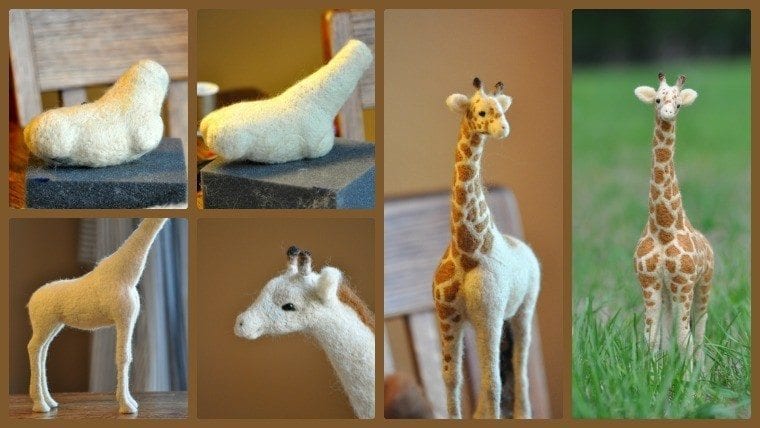

Felted 3D Sculpture

Creating a 3D sculpture through needle felting involves building upon a basic shape. Wool is added strategically to form the main body, while wire may be used in the legs for stability. The process often begins with the head, though sometimes it is made last. Achieving a smooth and firm texture is essential, especially when adding details such as spots. This meticulous process can take several days to complete, resulting in a stunning finished sculpture. A project like this takes several days to complete.

Wool

Various types of wool can be used in needle felting. Romney wool is a popular choice due to its firm felting properties, resulting in solid finished pieces. Merino wool is favored for its softness and is commonly used for flat felting. Wensleydale wool is known for its shiny curls, adding texture and character to creations. Experimenting with different types of wool can lead to exciting results. The Needle Felting Academy membership and sheep course provide access to a variety of wool types and guidance to help you find your favorites. My sheep course which is accessable through the Needle Felting Academy membership includes many different types of wool in the kit, to help you find your favorites right away. In 2016 I started felting through the sheep breeds where I share my experiences and thoughts on felting with all different types of wool.

Wet Felting

In addition to needle felting, some projects and kits may involve wet felting techniques. Wet felting utilizes hot soapy water instead of needles. By rubbing and agitating the wool fiber with water, it tangles and locks together. This technique is often used for flat felting, resulting in smooth and versatile felted fabric. Detailed instructions, pictures, videos, and personal guidance are available through our Needle Felting Academy and kits.

What is roving?

Roving refers to wool that has been washed and carded, aligning all the fibers in the same direction. Carding involves combing the wool to smooth out the locks and create a long, fluffy “roving” that can be spun into yarn or used for felting. Hand-painted roving is a visually appealing option for needle felting projects.

For more information on carding and how our wool is processed in our very own mill check out this video.

A short video of a needle felting work in progress.

Sustainable Crafting with Bear Creek Felting

Welcome to Bear Creek Ranch and Bear Creek Felting, where sustainability isn't just a buzzword; it's a way of life. As we commemorate Earth Day, we're excited to showcase how our company and products embody eco-friendly practices from start to finish. Join us as we...

Are Felting Needles Barbed?

When it comes to the world of felting, one of the most essential tools in your arsenal is undoubtedly the felting needle. These little wonders have the power to transform loose fibers into beautiful and sturdy creations. However, there's a common misconception about...

My Second Annual Needle Felting Safari: Crafting, Friendship, and Wildlife at Nome Schoolhouse

Picture this: a week at the Nome Schoolhouse, nestled in the heart of breathtaking historic beauty, surrounded by eight talented individuals eager to explore the intricate world of advanced needle felting. This was the essence of the second annual Needle Felting...